Low Temperature Process Library

Overview

111 Available Units

Example Projects

LTP_Lib - Low Temperature Process Library

The Low Temperature Process Library has been designed for modeling low temperature energy conversion processes. It allows you to design and analyze Organic Rankine Cycles (ORC), Supercritical CO2 Cycles (sCO2) and Kalina Cycles. LTP_Lib contains models for both design and off-design analysis.

Working Fluids

The Low Temperature Process Library contains five groups of working fluids:

- Organic working fluids

- Ammonia-Water mixtures as working fluid

- Heat transfer fluids (thermofluids) like thermo oils and salt mixtures

- Water

- Gaseous working fluids

Library Author

SimTech GmbH

Keywords

Organic Rankine Cycle, ORC, Kalina Cycle, Supercritical CO2

Version

6.6.18

First Published

7/2008

|

A_Condenser

condenser for NH3/H2O mixtures, water cooled

|

|

A_Condenser_a

condenser forNH3/H2O mixtures, air cooled, dry

|

|

A_Connector

connector for NH3/H2O mixtures to be used in closed loops

|

|

A_Flash

flash chamber for NH3/H2O mixtures

|

|

A_G_Htex

heat exchanger for transfer from NH3/H2O mixtures on hot side to gas on cold side

|

|

A_Htex

general purpose heat exchanger for NH3/H2O mixtures

|

|

A_Mixer

mixer for NH3/H2O mixtures

|

|

A_Pipe

pipe for NH3/H2O mixtures

|

|

A_Splitter

splitter for NH3/H2O mixtures

|

|

A_Sink

sink for a NH3/H2O stream

|

|

A_Source

source for a NH3/H2O stream

|

|

A_Turbine

turbine for NH3/H2O mixtures

|

|

A_T_Htex

heat exchanger for transfer from NH3/H2O mixture on hot side to a thermofluid on cold side

|

|

A_Valve

valve for NH3/H2O mixtures

|

|

A_W_Htex

heat exchanger for transfer from NH3/H2O mixture on hot side to water on cold side

|

|

A_Xprescription

prescription/calculation of the fluid quality for NH3/H2O mixtures

|

|

A_Pump

pump for NH3/H2O mixtures

|

|

gear

gears

|

|

generator

generator

|

|

G_Analyzer

gas analyzer gives detailed information on gas composition

|

|

G_A_Htex

heat exchanger for transfer from gas on hot side to NH3/H2O mixtures on cold side

|

|

G_Ambient_Sink

release of a gas stream at ambient pressure

|

|

G_Ambient_Source

source for an air stream at ambient conditions

|

|

G_Compressor

gas compressor

|

|

G_Condenser

gas condenser, water cooled

|

|

G_Connector

connector for gas streams to be used in closed loops

|

|

G_Htex

general purpose heat exchanger for gases

|

|

G_Heat_sink

heat sink for gas streams

|

|

G_Heat_source

heat source for gas streams

|

|

G_Mixer

mixer for gas streams

|

|

G_O_Htex

heat exchanger for transfer from gas on hot side to organic fluid on cold side

|

|

G_Pipe

pipe for gas streams

|

|

G_Sink

sink for a gas stream

|

|

G_Source

source for a gas stream

|

|

G_Splitter

splitter for gas streams

|

|

G_Stream_to_stream

transition piece to change from G_Streams to streams

|

|

G_Turbine

turbine for gaseous fluids

|

|

G_T_Htex

heat exchanger for transfer from gas on hot side to thermofluids on cold side

|

|

G_Valve

valve for gas

|

|

G_W_Htex

heat exchanger for transfer from gas on hot side to water on cold side

|

|

mech_loss

mechanical loss

|

|

motor

motor

|

|

optimization

optimization element

|

|

O_Boiler

simple boiler model for ORC fluids

|

|

O_Compressor

compressor for ORC fluids

|

|

O_Condenser

condenser for ORC fluids, water cooled

|

|

O_Condenser_a

condenser for ORC fluids, air cooled, dry

|

|

O_Connector

connector for ORC streams to be used in closed loops

|

|

O_Expander

expander for ORC fluids

|

|

O_G_Htex

heat exchanger for transfer from ORC fluid on hot side to gas on cold side

|

|

O_Htex

general purpose heat exchanger for ORC fluids

|

|

O_Mixer

mixer for ORC streams

|

|

O_Pipe

pipe for ORC fluids

|

|

O_Pump

pump for ORC fluids

|

|

O_Separator

vapour-liquid separator for ORC fluids

|

|

O_Splitter

splitter for ORC streams

|

|

O_Sink

sink for an ORC stream

|

|

O_Source

source for an ORC stream

|

|

O_Turbine

turbine for ORC fluids

|

|

O_T_Htex

heat exchanger for transfer from ORC fluid on hot side to thermofluid on cold side

|

|

O_Valve

valve for ORC fluid

|

|

O_W_Htex

heat exchanger for transfer from ORC fluid on hot side to water on cold side

|

|

O_Xprescription

prescription/calculation of vapor quality of an ORC fluid

|

|

stream_to_G_Stream

transition piece to change from streams to G_Streams

|

|

stream_to_W_Stream

transition piece to change from streams to W_Streams

|

|

T_A_Htex

heat exchanger for transfer from thermofluid on hot side to NH3/H2O mixture on cold side

|

|

T_Connector

connector for heat transfer fluids to be used in closed loops

|

|

T_G_Htex

heat exchanger for transfer from thermofluid on hot side to gas on cold side

|

|

T_Heat_sink

heat sink for heat transfer fluids

|

|

T_Heat_source

heat source for heat transfer fluids

|

|

T_Htex

general purpose heat exchanger for heat transfer fluids

|

|

T_Mixer

mixer for heat transfer fluid streams

|

|

T_O_Htex

heat exchanger for transfer from thermofluid on hot side to ORC fluids on cold side

|

|

T_Pipe

pipe for heat transfer fluids

|

|

T_Pump

pump for heat transfer fluids

|

|

T_Splitter

splitter for heat transfer fluid streams

|

|

T_Sink

sink for a heat transfer fluid stream

|

|

T_Source

source for a heat transfer fluids

|

|

T_Valve

valve for heat transfer fluids

|

|

T_W_Htex

heat exchanger for transfer from thermofluid on hot side to water on cold side

|

|

W_A_Htex

heat exchanger for transfer from water on hot side to NH3/H2O mixtures on cold side

|

|

W_Boiler

simple water/steam boiler model

|

|

W_Condenser_a

steam condenser, air cooled, dry

|

|

W_Connector

connector for water streams to be used in closed loops

|

|

W_Condenser

steam condenser, water cooled

|

|

W_Cooling_Tower_dry

dry cooling tower

|

|

W_Cooling_Tower_wet

wet cooling tower

|

|

W_Deaerator

direct mixing preheater a.k.a. deaerator

|

|

W_Drum

steam drum

|

|

W_G_Htex

heat exchanger for transfer from water on hot side to gas on cold side

|

|

W_Htex

general purpose heat exchanger, water on both sides

|

|

W_Heat_sink

heat sink for water streams

|

|

W_Heat_source

heat source for water streams

|

|

W_Mixer

mixer for water streams

|

|

W_O_Htex

heat exchanger for transfer from water on hot side to organic fluid on cold side

|

|

W_Pipe

pipe for water

|

|

W_Preheater

preheater for water/steam cycles

|

|

W_Pump

pump for water

|

|

W_Reheater

simple reheater model

|

|

W_Separator

separator splitting water into condensate and steam

|

|

W_Sink

sink for a water stream

|

|

W_Source

source for a water stream

|

|

W_Splitter

splitter for water streams

|

|

W_Stream_to_stream

transition piece to change from W_Streams to streams

|

|

W_Turbine

steam turbine

|

|

W_Turbine_end

steam turbine, end stage

|

|

W_T_Htex

heat exchanger for transfer from water on hot side to thermofluids on cold side

|

|

W_Valve

valve for water

|

|

W_Xprescription

prescription/calculation of steam quality

|

|

conditional_setting

free conditional equation to set selected variables

|

|

free_var

free variable

|

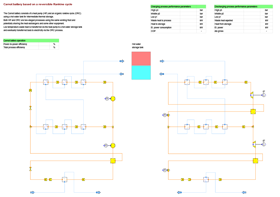

Carnot battery HP-ORC

The reversible combination of a heat pump and an organic rankine cycle process coupled via a thermal storage device forms a so-called Carnot battery. In this example both processes use the same working fluid and can share major process components as the heat exchangers.

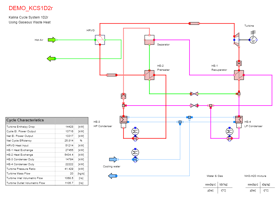

Demo_KCS1D2r

This project has no description.

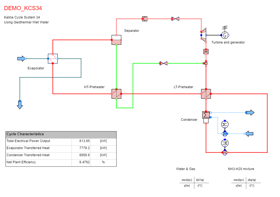

Demo_KCS34

This project has no description.

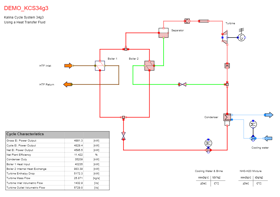

Demo_KCS34g3

This project has no description.

Demo_ORC_Cogeneration_Plant

This project has no description.

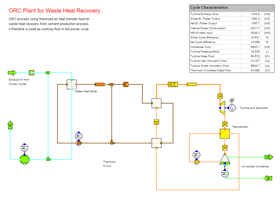

Demo_ORC_Plant_for_Waste_Heat_Recovery

This project has no description.

Demo_ORC_Recuperator_Air_Cooled

This project has no description.

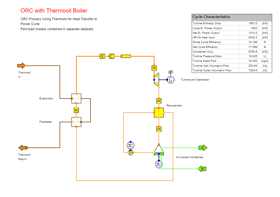

Demo_ORC_Thermooil_Boiler

This project has no description.

Demo_ORC_basic

This project has no description.

Demo_ORC_with_Recuperator

This project has no description.

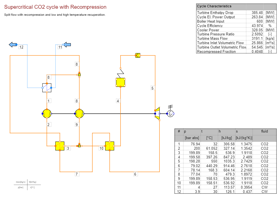

sCO2 Recompression Cycle

Supercritical CO2 cycle with split flow recompression and low and high temperature recuperation.

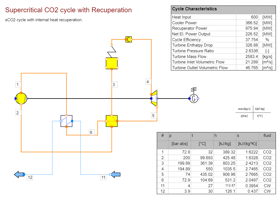

sCO2 Recuperated Cycle

Supercritical CO2 cycle with internal heat recuperation.

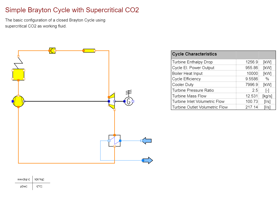

sCO2 Simple Brayton Cycle

The basic configuration of a closed Brayton cycle using supercritical CO2 as working fluid.