Desalination Process Library

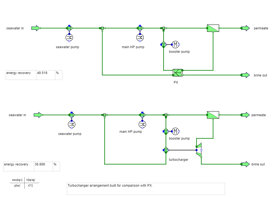

Desal_Lib, the Desalination Process Library, allows you to model and analyze desalination processes which use any of the major thermal and membrane based desalination technologies, including:

-

multi-stage flash (MSF)

-

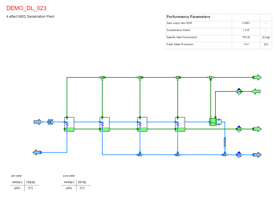

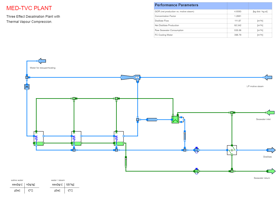

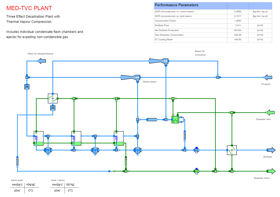

multiple effect desalination (MED)

-

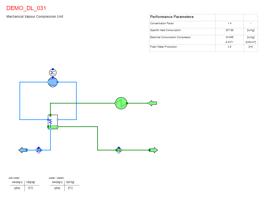

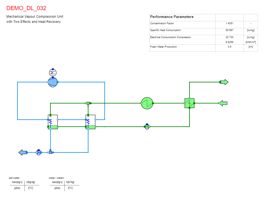

vapor compression (VC)

-

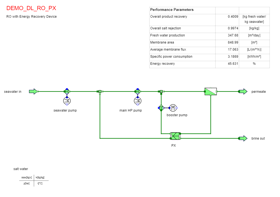

reverse osmosis (RO) and

-

combinations of the above mentioned processes.

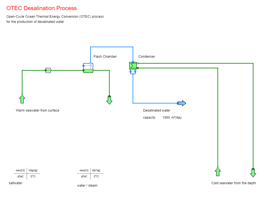

Desalination processes which are applied at a large industrial scale can be classified into two major types. These are thermal and membrane desalination processes. Among thermal desalination processes, multi-stage flash (MSF) distillation, multiple-effect distillation (MED) and vapor compression (VC) are the most important. Reverse osmosis (RO) is the main membrane desalination technology. There are several other desalination technologies like electrodialysis (ED), freezing, membrane distillation or solar humidification, but these only hold a very small share in the total installed desalination capacity.

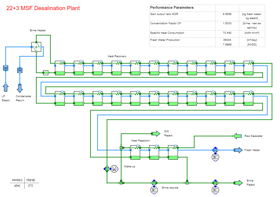

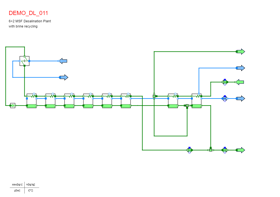

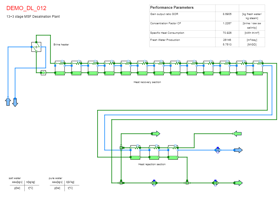

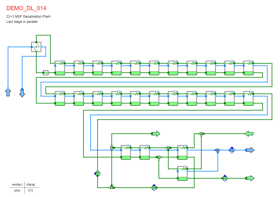

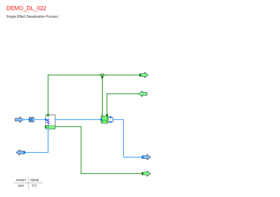

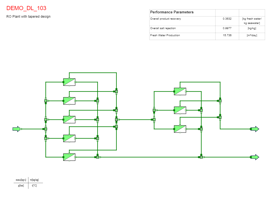

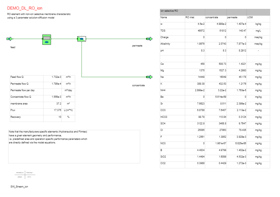

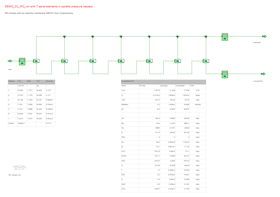

The desalination process library contains the necessary component models to design the various desalination processes mentioned above. These components typically represent individual pieces of equipment, like heat exchangers, pumps, valves etc.. The core components of standard desalination processes are included as single units in order to combine versatility with compactness of the library. For example, the individual stages of multi-stage processes are implemented as single units. Thereby a multi-stage flash plant with any number of stages can be built by connecting as many single stage components as there are real stages. On the other hand a single flash stage can still be further disassembled into separate basic operations like throttling, flashing, condensing and mixing. This is possible as well, as these simple unit operation models are also available to build individual stages from separate units. This has some benefits when it is necessary study certain effects in an individual stage. Yet when it comes to building a process model of an MSF plant, which may consist of more than 20 stages in large installations, the single stage model will be the preferred choice.

The models which are contained in the current version of the library are design models with a medium level of detail. They are just right to investigate whole-plant configurations and interactions between the different components.

For reverse osmosis desalination plants, the library contains extended models which take into account detailed ionic species in aqueous solutions. The carbonate system and boron equilibria are the prevailing weak acid systems in such solutions. The extended seawater streams with ionic species allow to calculate the pH-dependent carbonate and boron equilibria, and do charge balancing.

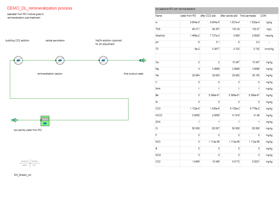

Models for remineralization and chemical dosing with various substances for water quality adjustment (pre- and posttreatment) have been added.

For reverse osmosis applications, RO models with ion specific membrane transfer equations have been developed.

Working Media

Salt Water: Saline water with variable salt content and ionic species

Water: Water and steam

Gases: Mixtures of one or more of the following ideal gases: Ar, C2H6, C3H8, CH4, CO, CO2, H2, H2O, H2S, N2, O2, SO2