Advanced Power Plant Library with Gas Turbines

Advanced Power Plant Library

APP_Lib, the Advanced Power Plant Library is used for modeling a wide range of thermal power systems. It supports both design and off-design analysis.

With the Advanced Power Plant Library the user can design and analyze any power plant, including:

- Conventional Power Plants

- Cogeneration Plants

- Combined Cycle Plants

The library supports both design of new plants as well as analysis and optimization of existing plants. The component models included with the Advanced Power Plant Library represent an optimum balance between:

- ease of use

- model accuracy

- amount of required input data

- flexibility

Working Media

Water

Water and steam

Gases

Mixtures of one or more of the following ideal gases: Ar, C2H6, C3H8, CH4, CO, CO2, H2, H2O, H2S, N2, O2, SO2

Fuels

Gases

CH4, C2H6, C3H8

Solid/liquid fuels

Solid/liquid fuels can be defined via their elementary analysis

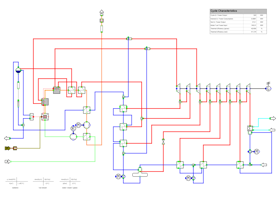

Boiler_Furnace_Steam_Cycle

This project has no description.

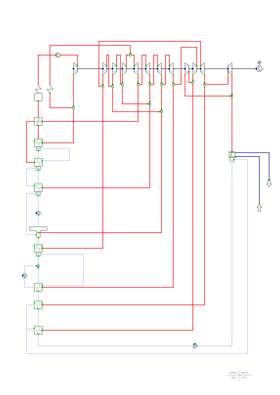

Combined Cycle with Bypass

This project has no description.

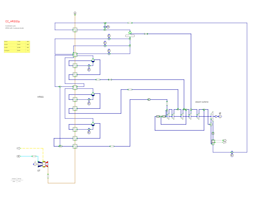

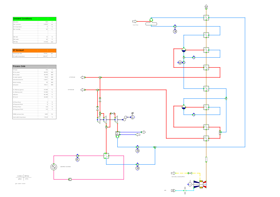

Combined Cycle with Dual Pressure HRSG

Combined cycle with two pressure levels in the heat recovery boiler

Combined Cycle with Tripel Pressure HRSG

Combined cycle with three pressure levels in the heat recovery boiler

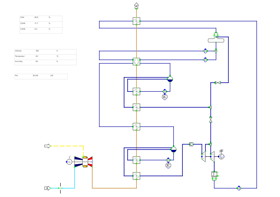

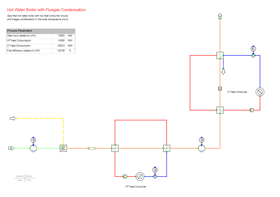

Hot Water Boiler with Fluegas Condensation

Gas fired hot water boiler with two heat consumer circuits and fluegas condensation in the lower temperature circuit.

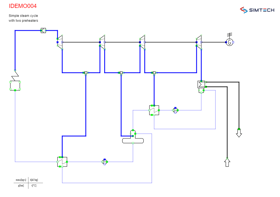

IDemo004

This project has no description.

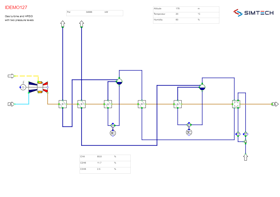

IDemo127

This project has no description.

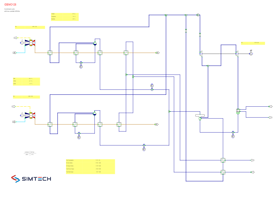

IDemo128

This project has no description.

IDemo_CombinedCycle2pHRSG_DistrictHeating

This project has no description.

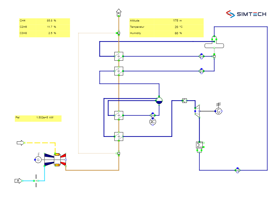

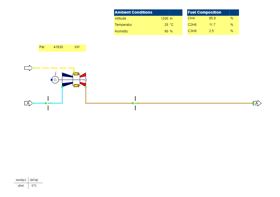

Stand_Alone_Gas_Turbine

A single stand-alone gas turbine model

Steam_Plant_001

This project has no description.